Versatile MPO Polishing Fixture: Adaptable to Various Polishing

Requirements

MPO Polishing Fixture Introduction

The MPO Polishing Fixture, model MT/PC & MT/APC, is a product of

advanced optical manufacturing technology, crafted with precision

in Guangdong, China, by Shenzhen Chuanglixun Optoelectronic

Equipment Co., Ltd. Since its inception in 2010, the company has

been at the forefront of innovation in the optical communications

equipment industry. It has established a strong reputation for

integrating R&D, production, after - sales service, and

technical support, all under one roof. This fixture represents a

pinnacle of design, engineered specifically for the high - density

polishing of MT/PC&MT/APC ferrules, meeting the most stringent

demands of modern optical connectivity.

MT polishing fixture Specifications

1. Machine Type | MT/PC | 2. Machine Size | D110*H45 mm | 3. Net Weight | 0.6 kg | 4. Capacity | 24 positions | 5. Application | Polishing MT/APC Ferrule | 6. Material | Stainless Steel S136 | 7. Suitable machines | CLX-M01 polishing machine

Seikoh Giken SFP-550 polishing machine

The similar machines | 8. Certification | CE |

|

MPO Polishing Fixture Function

Precision - engineered Polishing: During the polishing operation,

the fixture firmly secures the MT/APC ferrules, allowing for a

highly precise and dense polishing process. This results in an end

- face finish that is not only smooth but also consistent across

all surfaces. Such a high - quality finish is critical for

minimizing signal loss and maximizing optical performance, ensuring

that the fiber optic connectors meet the highest standards of

optical transmission.

Exceptional First - Pass Yield: The MPO Polishing Fixture achieves

an outstanding 95% first - pass yield for end - face quality. This

high success rate in the initial polishing attempt is a game -

changer in the production process. It significantly cuts down on

rework, which in turn saves both time and resources. Manufacturers

can increase their production throughput without sacrificing

quality, leading to greater overall efficiency.

Polishing Effect:

Geometry Test Result:

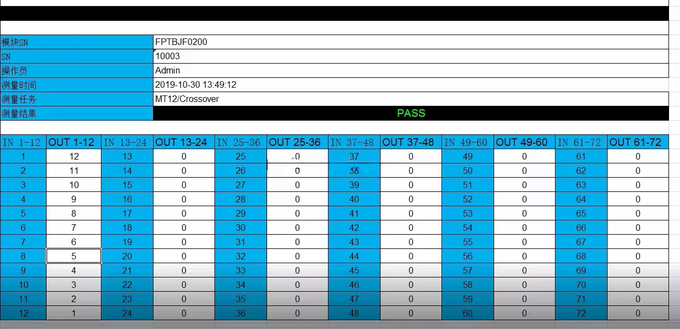

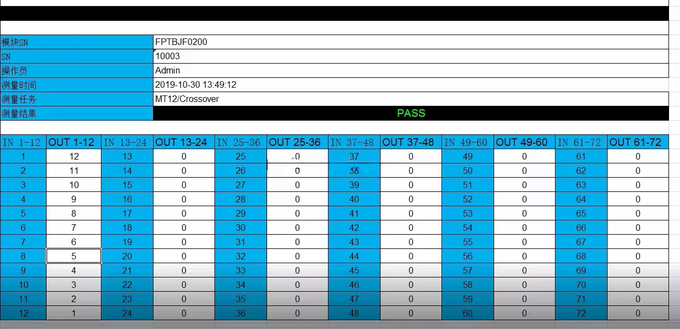

FPT Polarity Test:

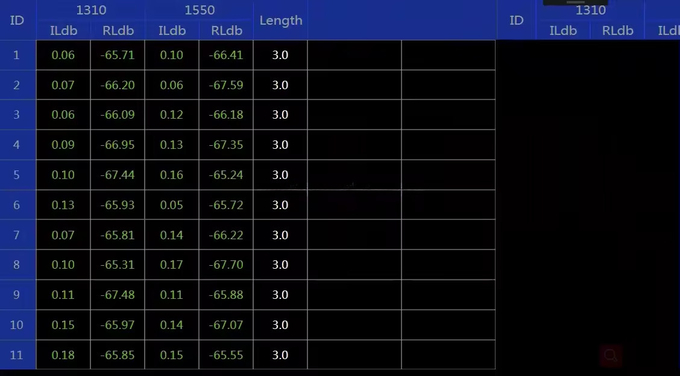

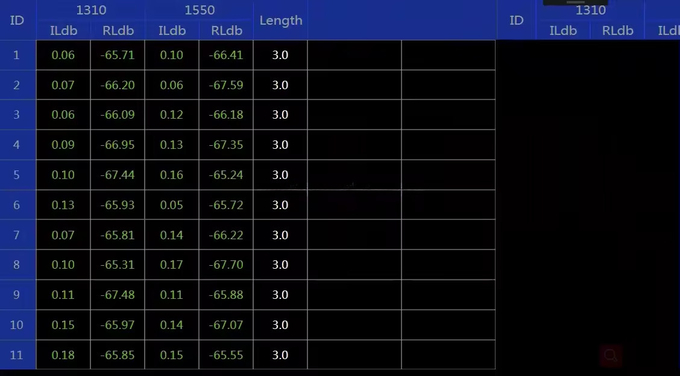

ILRL Test Result:

MPO Polishing Fixture Advantages

Efficiency Enhancement: One of the most significant advantages of

the MPO Polishing Fixture is its ability to revolutionize the

polishing process. Traditional polishing methods often suffer from

low efficiency, but this fixture, especially when paired with the

Neoholder® MT/APC, offers a dramatic improvement. It can increase

polishing efficiency several - fold without the need for additional

labor or equipment investment. This means that manufacturers can

produce more high - quality products in less time, giving them a

competitive edge in the market.

Time - saving Fixing Mechanism: The fixture's innovative design

greatly reduces the time required to fix the ferrules. This allows

workers to allocate more time to the actual polishing process,

rather than spending excessive time on setup. By streamlining the

workflow, it boosts overall productivity, enabling manufacturers to

meet tight production schedules and customer demands more

effectively.

Cost - effectiveness: By improving efficiency and minimizing

rework, the MPO Polishing Fixture offers a highly cost - effective

solution for fiber optic connector manufacturers. It optimizes the

production process, reducing waste and unnecessary expenses.

Businesses can achieve cost savings while maintaining the highest

levels of product quality, making it a smart investment for long -

term success.